Prototyping in Plastics - Choosing the Right Material For Your Prototype

Prototyping in plastics offers an efficient and cost-effective way to test and refine product designs before moving into full-scale production. Our primary focus is to work with our customers through the early design phase, supporting them from concept to production. We walk you through the material selection process to help you understand material options and benefits as they pertain to your specific application and needs.

Pre-Production Benefits

The pre-production benefits of plastics prototyping at Laminated Plastics include:

- Optimizing the manufacturing processes for your product.

- Demonstrate repeatable product performance.

- Provide several units (typically 10 to 100) for verification in your final system.

- Provide parts for additional certification testing (if required).

Plastic Prototypes Offer Several Advantages Over Metals:

- Cost-effective: Plastic materials are generally cheaper than metals or other materials used in prototyping, making them more cost-effective for initial iterations and testing.

- Versatility: Plastics come in a wide range of types, each with its own unique properties, such as flexibility, durability, transparency, and heat resistance. This versatility allows designers to choose the most suitable material for their specific prototype requirements.

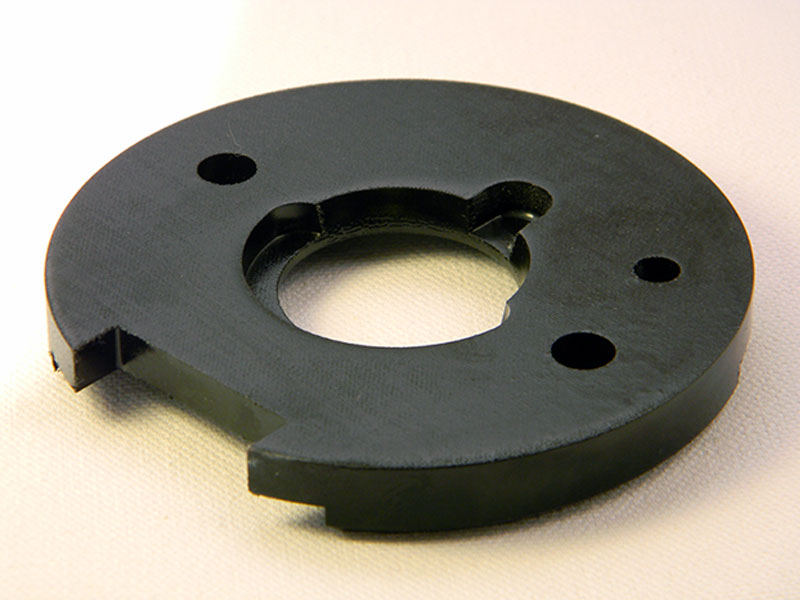

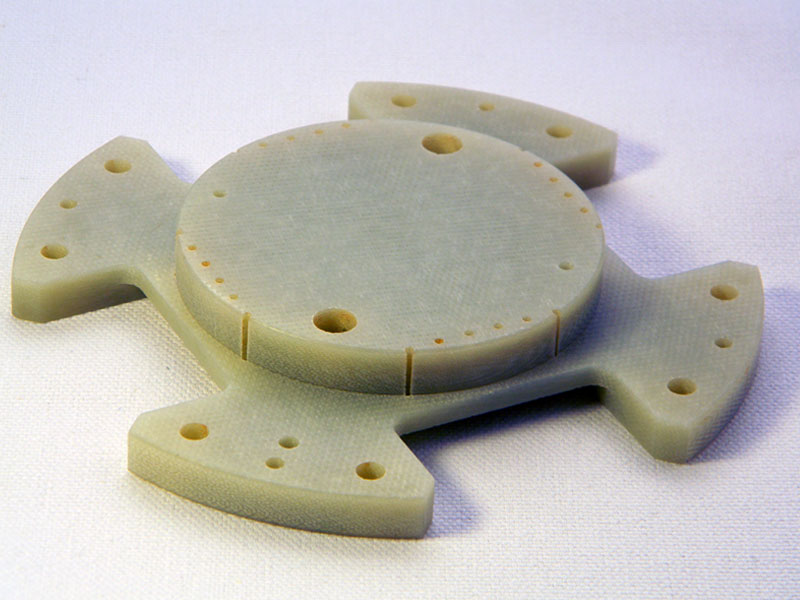

- Ease of fabrication: Plastics can be easily molded into complex shapes using techniques such as injection molding, 3D printing, or vacuum forming. This makes it easier to create prototypes that closely resemble the final product.

- Quick turnaround time: Plastic prototyping techniques like 3D printing allow for rapid production of prototypes, reducing lead times and speeding up the development process.

- Iterative design: Since plastic prototyping is relatively inexpensive and quick, designers can easily create multiple iterations of a prototype to refine and improve the design before finalizing production.

- Material testing: Plastic prototypes can be used to conduct material testing and performance evaluations before investing in expensive tooling for mass production.

- Visual representation: Plastic prototypes provide a visual representation of the final product, allowing stakeholders to better understand the design and provide feedback early in the development process.

Materials Validation and Testing

We can provide candidate material for evaluation and testing to ensure proper performance will be met and the selected plastic formulation satisfies all of your test requirements. We provide support through the testing phase until assurance is confirmed and a material is qualified to meet all application demands.

- Structural or wear application.

- Physical & mechanical considerations.

- Thermal and temperature requirements.

- Chemical resistance capacity.

- Additional certifications or specifications needed.